0.6/1KV PVC Insulated Armored Power Cable

Conductor Conductor should be Class 2 plain or metallic-coated annealed copper Color Customizable upon request. Construction: 1.Conductor: Clas ......

Email: jason@xienuoenterprise.com

Product Detail

Conductor

Conductor should be Class 2 plain or metallic-coated annealed copper

Color

Customizable upon request.

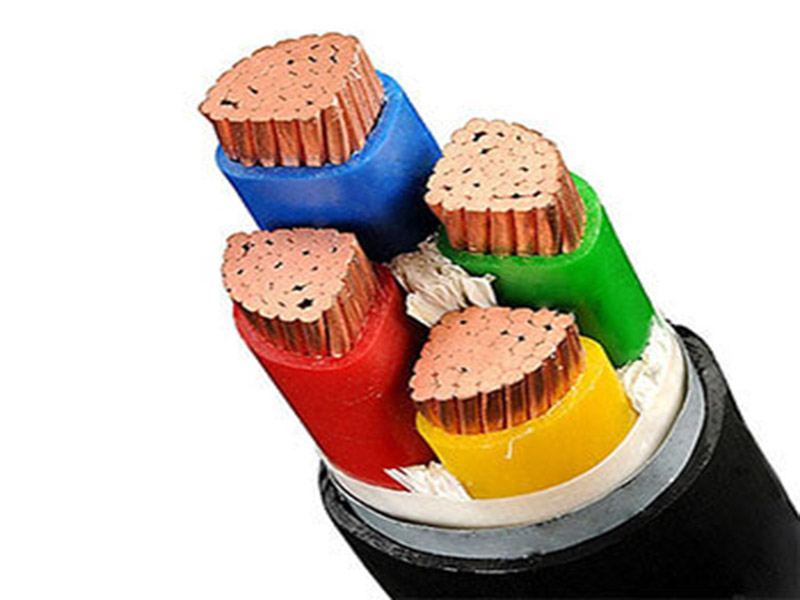

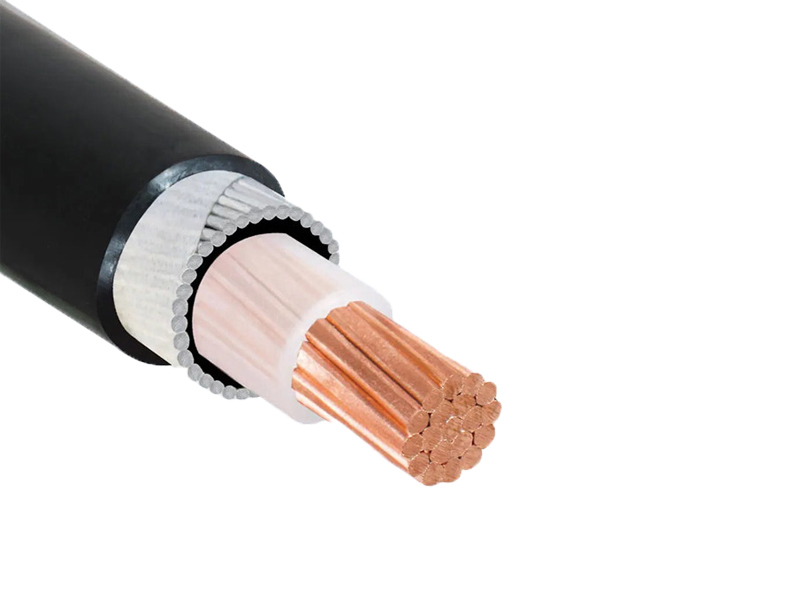

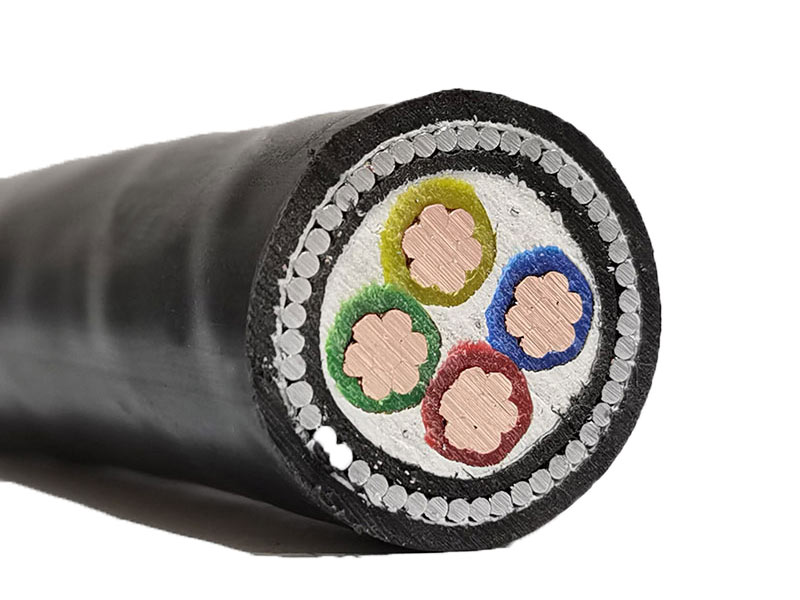

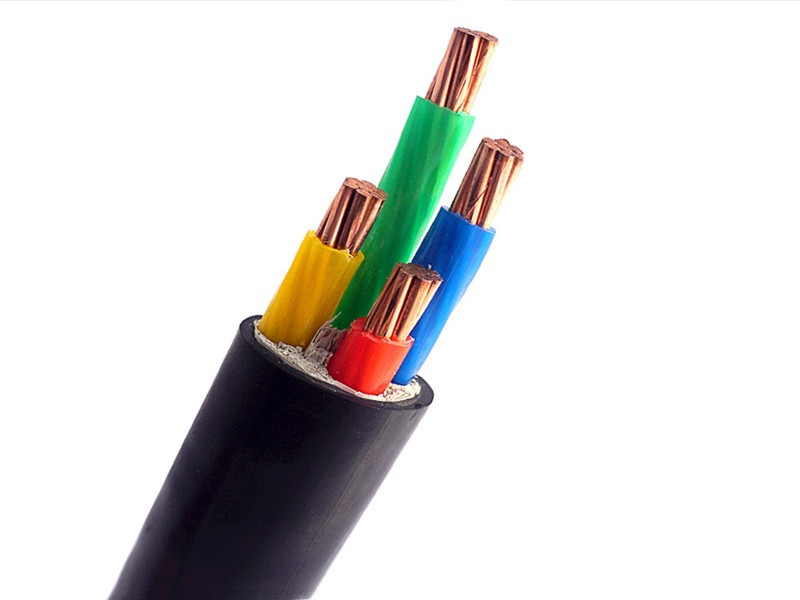

Construction:

1.Conductor: Class 2 stranded copper wire

2.Insulation: Polyvinyl chloride (PVC)

3.Inner sheath: Polyvinyl chloride (PVC)

4.Armor: Galvanized steel tape

5.Outer sheath: Polyvinyl chloride (PVC)

Applications of PVC Insulated and Armored Power Cables

These cables are used for power supply in low-voltage installations. They are suitable for indoor and outdoor installations, cable ducts, underground installations, power stations and switchyards, local energy distribution, industrial plants, and other locations without risk of mechanical damage. The lead sheath provides enhanced resistance to aromatic hydrocarbons.

Product Parameters

| Size | 2 Core Cable Data Sheet | Approx. Weight

|

|||||

| CU Conductor | Insulation | Outer Sheath | Approx. Overall Dia. | ||||

| Str. No. | Resistance | Nominal Thickness | Nominal Thickness | ||||

| Core No. | mm2 | No.s | Ω/km | mm | mm | mm | kg/km |

| 2 | 1.5 | 7 | 12.1 | 0.8 | 1.8 | 13.3 | 255 |

| 2 | 2.5 | 7 | 7.41 | 0.8 | 1.8 | 14.2 | 297 |

| 2 | 4 | 7 | 4.61 | 1.0 | 1.8 | 16.0 | 378 |

| 2 | 6 | 7 | 3.08 | 1.0 | 1.8 | 17.2 | 448 |

| 2 | 10 | 7 | 1.83 | 1.0 | 1.8 | 19.0 | 573 |

| 2 | 16 | 7 | 1.15 | 1.0 | 1.8 | 21.1 | 743 |

| 2 | 25 | 7 | 0.727 | 1.2 | 1.8 | 23.8 | 996 |

| 2 | 35 | 7 | 0.524 | 1.2 | 1.8 | 25.8 | 1231 |

| 2 | 50 | 7 | 0.387 | 1.4 | 1.8 | 29.1 | 1606 |

| 2 | 70 | 19 | 0.268 | 1.4 | 1.9 | 32.7 | 2090 |

| 2 | 95 | 19 | 0.193 | 1.6 | 2.1 | 38.9 | 3159 |

| 2 | 120 | 19 | 0.153 | 1.6 | 2.2 | 41.9 | 3762 |

| 2 | 150 | 19 | 0.124 | 1.8 | 2.4 | 46.0 | 4519 |

| 2 | 185 | 37 | 0.0991 | 2.0 | 2.5 | 51.0 | 5532 |

| 2 | 240 | 37 | 0.0754 | 2.2 | 2.7 | 57.0 | 6975 |

| Size | 3 Core Cable Data Sheet | Approx. Weight

|

|||||

| CU Conductor | Insulation | Outer Sheath | Approx. Overall Dia. | ||||

| Str. No. | Resistance | Nominal Thickness | Nominal Thickness | ||||

| Core No. | mm2 | No.s | Ω/km | mm | mm | mm | kg/km |

| 3 | 1.5 | 7 | 12.1 | 0.8 | 1.8 | 11.0 | 154 |

| 3 | 2.5 | 7 | 7.41 | 0.8 | 1.8 | 12.0 | 197 |

| 3 | 4 | 7 | 4.61 | 1.0 | 1.8 | 14.0 | 276 |

| 3 | 6 | 7 | 3.08 | 1.0 | 1.8 | 15.2 | 351 |

| 3 | 10 | 7 | 1.83 | 1.0 | 1.8 | 17.2 | 495 |

| 3 | 16 | 7 | 1.15 | 1.0 | 1.8 | 19.4 | 696 |

| 3 | 25 | 7 | 0.727 | 1.2 | 1.8 | 22.4 | 1008 |

| 3 | 35 | 7 | 0.524 | 1.2 | 1.8 | 24.6 | 1309 |

| 3 | 50 | 7 | 0.387 | 1.4 | 1.8 | 28.1 | 1781 |

| 3 | 70 | 19 | 0.268 | 1.4 | 2.0 | 32.1 | 2417 |

| 3 | 95 | 19 | 0.193 | 1.6 | 2.1 | 36.9 | 3273 |

| 3 | 120 | 19 | 0.153 | 1.6 | 2.2 | 40.1 | 4033 |

| 3 | 150 | 19 | 0.124 | 1.8 | 2.3 | 44.3 | 4948 |

| 3 | 185 | 37 | 0.0991 | 2.0 | 2.5 | 49.5 | 6175 |

| 3 | 240 | 37 | 0.0754 | 2.2 | 2.7 | 56.0 | 8020 |

| Size | 4 Core Cable Data Sheet | Approx. Weight

|

|||||

| CU Conductor | Insulation | Outer Sheath | Approx. Overall Dia. | ||||

| Str. No. | Resistance | Nominal Thickness | Nominal Thickness | ||||

| Core No. | mm2 | No.s | Ω/km | mm | mm | mm | kg/km |

| 4 | 1.5 | 7 | 12.1 | 0.8 | 1.8 | 11.8 | 184 |

| 4 | 2.5 | 7 | 7.41 | 0.8 | 1.8 | 12.9 | 238 |

| 4 | 4 | 7 | 4.61 | 1.0 | 1.8 | 15.2 | 340 |

| 4 | 6 | 7 | 3.08 | 1.0 | 1.8 | 16.6 | 439 |

| 4 | 10 | 7 | 1.83 | 1.0 | 1.8 | 18.7 | 623 |

| 4 | 16 | 7 | 1.15 | 1.0 | 1.8 | 21.3 | 887 |

| 4 | 25 | 7 | 0.727 | 1.2 | 1.8 | 24.6 | 1293 |

| 4 | 35 | 7 | 0.524 | 1.2 | 1.8 | 27.0 | 1686 |

| 4 | 50 | 7 | 0.387 | 1.4 | 1.9 | 31.2 | 2320 |

| 4 | 70 | 19 | 0.268 | 1.4 | 2.1 | 35.7 | 3153 |

| 4 | 95 | 19 | 0.193 | 1.6 | 2.2 | 41.0 | 4273 |

| 4 | 120 | 19 | 0.153 | 1.6 | 2.4 | 44.8 | 5295 |

| 4 | 150 | 19 | 0.124 | 1.8 | 2.5 | 49.4 | 6492 |

| 4 | 185 | 37 | 0.0991 | 2.0 | 2.7 | 55.2 | 8100 |

| 4 | 240 | 37 | 0.0754 | 2.2 | 2.9 | 62.4 | 10521 |

| Size | 4 Core Cable Data Sheet | Approx. Weight

|

|||||

| CU Conductor | Insulation | Outer Sheath | Approx. Overall Dia. | ||||

| Str. No. | Resistance | Nominal Thickness | Nominal Thickness | ||||

| Core No. | mm2 | No.s | Ω/km | mm | mm | mm | kg/km |

| 4 | 1.5 | 7 | 12.1 | 0.8 | 1.8 | 11.8 | 184 |

| 4 | 2.5 | 7 | 7.41 | 0.8 | 1.8 | 12.9 | 238 |

| 4 | 4 | 7 | 4.61 | 1.0 | 1.8 | 15.2 | 340 |

| 4 | 6 | 7 | 3.08 | 1.0 | 1.8 | 16.6 | 439 |

| 4 | 10 | 7 | 1.83 | 1.0 | 1.8 | 18.7 | 623 |

| 4 | 16 | 7 | 1.15 | 1.0 | 1.8 | 21.3 | 887 |

| 4 | 25 | 7 | 0.727 | 1.2 | 1.8 | 24.6 | 1293 |

| 4 | 35 | 7 | 0.524 | 1.2 | 1.8 | 27.0 | 1686 |

| 4 | 50 | 7 | 0.387 | 1.4 | 1.9 | 31.2 | 2320 |

| 4 | 70 | 19 | 0.268 | 1.4 | 2.1 | 35.7 | 3153 |

| 4 | 95 | 19 | 0.193 | 1.6 | 2.2 | 41.0 | 4273 |

| 4 | 120 | 19 | 0.153 | 1.6 | 2.4 | 44.8 | 5295 |

| 4 | 150 | 19 | 0.124 | 1.8 | 2.5 | 49.4 | 6492 |

| 4 | 185 | 37 | 0.0991 | 2.0 | 2.7 | 55.2 | 8100 |

| 4 | 240 | 37 | 0.0754 | 2.2 | 2.9 | 62.4 | 10521 |

| Size | 5 Core Cable Data Sheet | Approx. Weight

|

|||||

| CU Conductor | Insulation | Outer Sheath | Approx. Overall Dia. | ||||

| Str. No. | Resistance | Nominal Thickness | Nominal Thickness | ||||

| Core No. | mm2 | No.s | Ω/km | mm | mm | mm | kg/km |

| 5 | 1.5 | 7 | 12.1 | 0.8 | 1.8 | 12.7 | 216 |

| 5 | 2.5 | 7 | 7.41 | 0.8 | 1.8 | 14.0 | 284 |

| 5 | 4 | 7 | 4.61 | 1.0 | 1.8 | 16.5 | 408 |

| 5 | 6 | 7 | 3.08 | 1.0 | 1.8 | 18.0 | 528 |

| 5 | 10 | 7 | 1.83 | 1.0 | 1.8 | 20.4 | 756 |

| 5 | 16 | 7 | 1.15 | 1.0 | 1.8 | 23.3 | 1084 |

| 5 | 25 | 7 | 0.727 | 1.2 | 1.8 | 27.0 | 1587 |

| 5 | 35 | 7 | 0.524 | 1.2 | 1.9 | 29.9 | 2090 |

| 5 | 50 | 7 | 0.387 | 1.4 | 2.1 | 34.7 | 2891 |

| 5 | 70 | 19 | 0.268 | 1.4 | 2.2 | 39.5 | 3910 |

| 5 | 95 | 19 | 0.193 | 1.6 | 2.4 | 45.6 | 5324 |

| 5 | 120 | 19 | 0.153 | 1.6 | 2.5 | 49.6 | 6571 |

| 5 | 150 | 19 | 0.124 | 1.8 | 2.7 | 54.9 | 8084 |

| 5 | 185 | 37 | 0.0991 | 2.0 | 2.9 | 61.3 | 10081 |

| 5 | 240 | 37 | 0.0754 | 2.2 | 3.1 | 69.3 | 13093 |

Henan Xienuo Enterprise Co., Ltd.

The main products include steel wire, steel strand, galvanized steel strand, aluminum coil, aluminum plate, aluminum strip, aluminum foil, aluminum discs, color-coated aluminum coil, copper wire, and cables. The products are widely used in various fields such as power cables, overhead power lines, automobiles, ships, building decoration, etc.

Why Choose US

Our company has a wide range of businesses and a diverse product lines. As of now, we have directly invested in factories such as Henan Xuntai Aluminum New Materials Co., Ltd., Henan Xiecheng Aluminum Co., Ltd., Sichuan Guangyuan High-strength Wire Materials Co., Ltd. and Henan Hongfeng Cable Co., Ltd. Nationwide, we have over 100,000 square meters of factory and office space, approximately 1,200 employees, and the annual output value of over 100 billion yuan.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

Based on the principles of "Integrity First", "Quality First" and "Customer First", relying on the advanced production equipments, scientific management system, strict production process, as well as professional R&D and sales teams, our products have been sold far and wide to over 150 countries and regions at home and abroad, earning widespread acclaim and trust from customers both domestically and internationally.